Cooling Production

Cooling Production

The district cooling system operates year round with no seasonal or scheduled shutdowns. It has been extremely reliable due to the distributed nature of the production facilities and the use of the Thermal Storage Tank. This distributed production capability allows Cornell to conduct equipment and piping repairs within the plants themselves without interruptions to the customers. Individual equipment failures or trips are countered by quickly shifting load to the Thermal Storage Tank.

Since the start-up in July 2000 of the system's flagship Lake Source Cooling plant, LSC has reliably captured 99% of the annual cooling load. In 2005, all CFC refrigerant chillers in the three other central cooling plants were decommissioned. In addition to Lake Source Cooling, this leaves just two hydrofluorocarbon (HFC) Chillers, plus the Thermal Storage Tank, as supplemental supply and back-up to LSC. A summary of these cooling resources is shown in the table below.

Resource | Capacity (tons) | Manufacturer | Model | Year Installed | kW/ton |

|---|---|---|---|---|---|

Lake Source Cooling | 20,000 | N/A | N/A | 2000 | 0.10 |

Chiller 4 | 1,450 | Carrier | 19FA | 1974 | N/A |

Chiller 7 | 4,000 | Carrier | 17DA | 1987 | 0.65 |

Chiller 8 | 2,300 | Carrier | 17EX | 1996 | 0.63 |

Thermal Storage Tank | 4,000 | 4.5 Million Gallons | Stratified Water | 1991 | N/A |

The Lake Source Cooling (LSC) project was a replacement and upgrade of the central campus chilled water system with a more environmentally sound design. In 1994, pressures on the existing outmoded, 1960’s era system, such as CFC phase-out, load growth, aging equipment and rising energy costs, necessitated a substantial change. LSC was chosen as the best available technology from the numerous options studied. Construction began in the spring of 1999, with start-up and commissioning occurring during the summer of 2000. Though it requires more initial investment than replacing the system with standard refrigeration technology, LSC is providing the university with a method of cooling that eliminates CFC-containing refrigeration equipment and its associated energy use.

LSC draws water through a 2mm wedge-wire screened intake about 10 feet above the lake bottom, at a water depth of 250 feet. At this depth, Cayuga Lake remains cold (about 39°F) year-round. The cold water is piped to a shoreline heat exchange facility, where it transfers its coldness through solid stainless-steel plates to water that circulates to the campus in a second loop of pipeline. The two water flows can never mix. Water drawn from deep in the lake is returned through a diffuser located about 500 feet offshore, at a water depth of 10 ft. The water is returned to the lake at a temperature between 50-55°F, and no chemicals of any kind are added to the recirculated lake water. The chilled campus water is pumped up to the campus to cool equipment and buildings via a closed-loop system. Because heat flows naturally from hot to cold, no extra energy is required beyond that needed to move the water through the pipes.

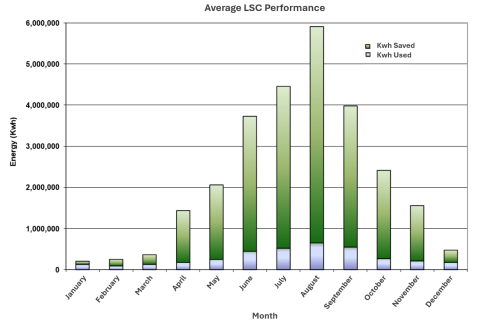

The renewable resources tapped by LSC have reduced Cornell’s reliance on fossil fuels. Since coming online, LSC typically saves 25,000,000 kilowatt-hours of electricity annually, enough to supply 2500 homes in Tompkins County. This represents about an 85% reduction in energy use for campus cooling. Energy savings for an average year are depicted in the chart below.

District Cooling System Energy Conservation Projects

Chiller 7 variable speed drive

The 3500-horsepower (4000-ton) electric motor-driven chiller, completed in 1987, was designed with a variable-speed drive, the first of its kind by Carrier Corporation worldwide. This chiller uses 40% less electricity than a standard constant-speed motor-driven unit.

Chilled water pump variable speed drives

From 1987 to 1990, centrifugal pumps that move chilled water through the chillers and the distribution system piping were converted to infinitely variable flow using variable-speed drives from 125 to 350 horsepower. 3300 horsepower pumps, in total, significantly reduced pumping energy use and allowed plant flows and pressures to exactly match campus varying needs. Cornell was one of the first campus systems to utilize the large central plant pump drives.

Thermal storage tank

Starting in 1991, a 4.4-million-gallon insulated stratified chilled water thermal storage tank allowed the shifting of 40,000 ton-hrs of cooling from day to night. The higher efficiencies possible at night and the use of off-peak electricity, decreased cooling energy use and electricity costs. Overall, campus production efficiency was increased by 10% due to the use of cooler nighttime air for refrigerant cycle heat rejection.

Chilled water plant 3 free cooling

Cooling for the campus chilled water can be provided by a 1,000-ton heat exchanger rejecting heat to a cooling tower installed in 1987. Cold outside air cools the cooling tower below the temperature of the campus chilled water, allowing the heat to flow from hot to cold without the need for refrigeration. This project won a national award for energy cost savings.

Chilled water plant 1 free cooling

This 1,500-ton project, completed in 1989, supplemented the previous free cooling effort by cooling the campus for much longer each year using Fall Creek water as a natural heat sink through a heat exchanger (non-contact cooling). The elimination of refrigeration and a cooling tower further reduced energy use, and the more constant creek water temperature eliminated four months of refrigeration each year.

Chilled water plant automation and distributed digital controls

Over the course of four years, from 1987 to 1991, all three chilled water plants were fully automated with distributed digital controls to allow for the best dispatch and highest efficiency operation of seven campus chillers. All auxiliary equipment and chillers' energy use was minimized by computer logic and operator decisions each day.

Lake Source Cooling Project

The Cornell University Energy & Sustainability Department commissioned an innovative deep water source cooling project using a renewable resource, the deep, cold waters of nearby Cayuga Lake, as a non-contact cooling source for the campus chilled water system. The Lake Source Cooling (LSC) Project began providing 16,000 tons of cooling to the campus in July 2000 with an 87% reduction in energy use versus conventional cooling alternatives (a savings of over 20 million kWh per year, enough for 2,500 homes). LSC has been described as "a project that supports a sustainable future." All indications to date support this statement. For more information, please visit the LSC website.